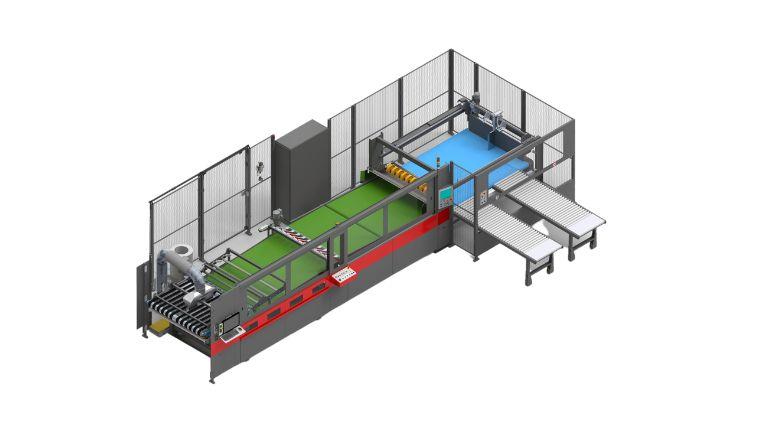

BUNDLE STACKER - BundStack

Bundle Stacker for Digital Printing Lines

Overview

Bundle stacking solution for digital printing lines

The corrugated board industry often faces the challenge of manual stacking of bundles, which can be time-consuming and labor-intensive. However, the Compact Corrugated Board Bundle Stacker from SERRA offers a solution to this problem by providing a continuous workflow bundle stacker. This equipment offers several benefits that can help streamline the manual stacking process, reduce waste, and save space in the production facility.

The Compact Corrugated Board Bundle Stacker from SERRA provides several benefits that can help streamline the manual stacking process, reduce waste, and save space in the production facility. Its continuous workflow, improved space utilization, low TCO, and high-quality output make it an ideal solution for the corrugated board industry.

Continuous Workflow Bundle Stacker

- Continuous sheet transport system

- Seamless workflow with minimal interruptions

- Smooth and continuous separation of bundles, saving time and increasing productivity

Improved Space Utilization

- Compact design

- Optimizes space utilization in the production facility

- Length is approximately two and a half times the length of the sheet, making it easy to install in any workspace

Low TCO

- Cost-efficient solution

- Requires low maintenance

- Reduces the risk of workplace injuries and improves overall efficiency, reducing the total cost of ownership

High-Quality Output

- Equipped with a top tray

- Enables operators to obtain samples without interrupting the work process

- Allows for quality control checks to be carried out during the process, ensuring high-quality output

Features

Continuous Workflow Bundle Stacker:

The system offers a continuous sheet transport system that ensures a seamless workflow with minimal interruptions. The smooth and continuous separation of bundles saves time and increases productivity.

Improved Space Utilization:

The system has a compact design that optimizes space utilization in the production facility. Its length is approximately two and a half times the length of the sheet, making it easy to install in any workspace.

Low TCO:

The system is a cost-efficient solution that requires low maintenance. It reduces the risk of workplace injuries and improves overall efficiency, reducing the total cost of ownership.

High-Quality Output

The system is equipped with a top tray that enables operators to obtain samples without interrupting the work process. This allows for quality control checks to be carried out during the process, ensuring high-quality output.

Sheet Stacking Capacity:

The system can handle a wide range of sheet sizes, weights, and bundle heights, making it a versatile solution for the corrugated board industry.

Customizable Configurations:

The system can be precisely configured to the characteristics of the floor space, making it suitable for businesses with limited space.

User-Friendly Interface:

The system has a user-friendly interface that enables operators to easily adjust the settings and monitor the workflow.

Durable and Robust Construction:

The system is made of high-quality materials that ensure durability and robustness, making it a long-lasting solution for the corrugated board industry.