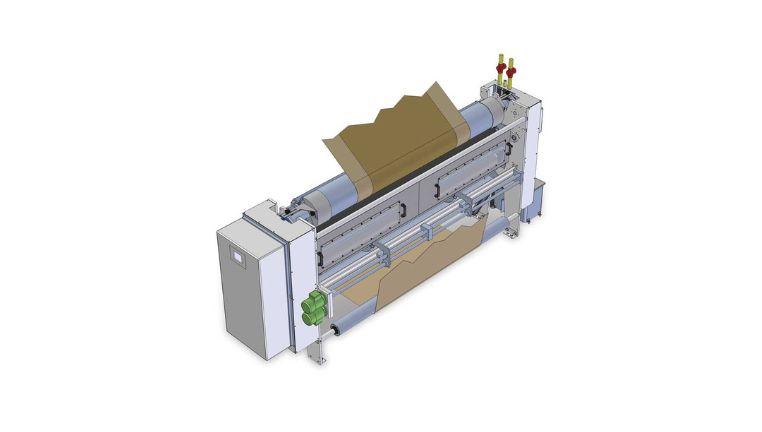

WAX APPLICATOR - WaxApp

Anti-splash hot wax applicator

Overview

Advanced hot wax applicator

Hot wax applicators are essential machines for businesses in the printing and finishing industry. SERRA's hot and cold wax applicators are advanced solutions that offer a wide range of applications and can operate at any line speed.

SERRA's hot wax applicators offer numerous benefits for businesses in the printing and finishing industry. From ensuring a clean work area and providing easy digital control to versatility in applying both cold and hot wax, these machines can help businesses save time and money while maintaining high-quality standards. By using the key phrase "Hot Wax Applicator" in your SEO strategy, your business can attract more potential customers who are searching for this essential tool.

Work clean

- The anti-splashing design of SERRA's hot wax applicators helps to prevent wax from splattering during the application process, ensuring a clean work area.

- This feature also reduces the risk of contamination of the finished product, ensuring that your business maintains high-quality standards.

- A clean work area also improves the working environment for employees, reducing the risk of accidents and injuries.

Digital Control Screen

- SERRA's hot wax applicators come with a digital control screen that provides easy and intuitive control over the wax application proces

- The limiters are controlled via a touchscreen, which makes it easier to adjust the machine's settings according to your business's specific needs.

- The regulation control of the top roller also helps to minimize wear of the central rubber roller, increasing the lifespan of the machine.

Versatity cold and hot wax

- SERRA's hot wax applicators are highly versatile and can apply both cold and hot wax to a variety of products, including corrugated cardboard and paperboard.

- The hot wax fusion tank helps to maintain the optimal temperature for the wax, while the serpentines on the tray help to maintain the wax temperature during the application process.

- This feature ensures that the wax is applied uniformly and consistently, resulting in a high-quality finished product.

Saving time and money

- SERRA's hot wax applicators allow for the application of the minimum amount of wax in a uniform and regular manner, reducing waste and increasing efficiency.

- This feature is particularly important for businesses that operate at high line speeds, as it helps to speed up the production process and reduce labor costs.

- By using a hot wax applicator, businesses can save money on wax consumption, as the machine applies only the required amount of wax, reducing waste and saving money in the long run.