ROBOT STACKER - BotStack

Robotic Sheet Handling for Digital Printing Lines

Overview

Automated stacking solutions for digital printing lines

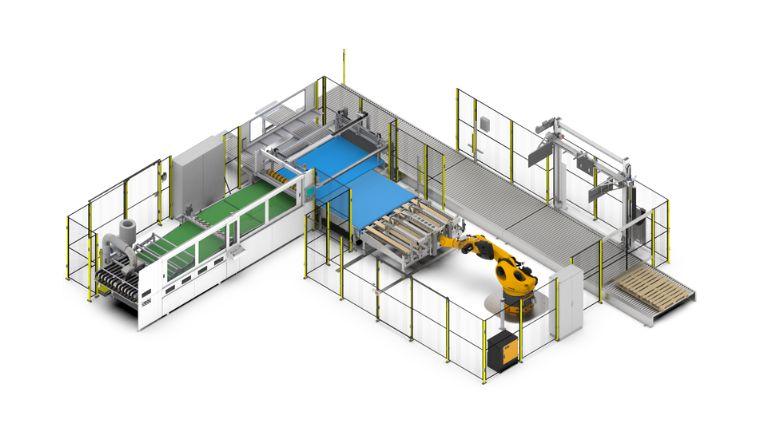

The Selective Sheet Flipper Robot Stacker is an advanced robotic system designed to handle cardboard sheet bundles in the corrugated board industry. This innovative system is a game-changer for digital printing lines, as it offers automated stacking solutions and robotic sheet handling capabilities. The Stacker High Line from SERRA is an ideal solution for businesses looking to optimize their operations and increase productivity.

SERRA's Selective Sheet Flipper Robot Stacker is an innovative robotic system that offers several benefits for digital printing lines in the corrugated board industry. Its flexibility, automated stacking solutions, simple and maintenance-friendly design, and high-quality results make it an ideal solution for businesses looking to optimize their operations and increase productivity. By investing in the Selective Sheet Flipper Robot Stacker, businesses can reduce manual labor, improve efficiency, and achieve high-quality results, ultimately driving growth and success.

Flexibility

- The Selective Sheet Flipper Robot Stacker has several configurations that can be precisely adapted to the characteristics of the floor space.

- This feature is particularly useful for businesses with limited space, as it enables the system to be installed in even the smallest of spaces.

- The system's flexibility allows it to handle different sheet sizes and weights, making it a versatile solution for digital printing lines.

Automated stacking solutions

- The Selective Sheet Flipper Robot Stacker is an automated solution that eliminates the need for manual labor.

- This system allows businesses to stack sheets efficiently and accurately, reducing the risk of workplace injuries and improving productivity.

- The system's robotic sheet handling capabilities help to reduce errors and improve the quality of the final product.

Simple and maintenance-friendly design

- The Selective Sheet Flipper Robot Stacker has a simple, compact, and maintenance-friendly design that makes it easy to operate and maintain.

- This system is designed to be easy to clean, reducing downtime and maximizing uptime.

- The maintenance-friendly design of this system reduces the need for specialized technicians, making it a cost-effective solution for businesses.

High-quality results

- The Selective Sheet Flipper Robot Stacker ensures final bundle squaring through the use of lateral and rear stoppers and the robot’s clamp.

- This feature is particularly useful for digital printing lines, as it ensures high-quality bundles that are essential for producing top-notch prints.

- The final bundle squaring capability of this system helps to reduce waste, thereby increasing efficiency and reducing costs.

Features

Multiple Configurations:

The system can be precisely configured according to the floor space, making it suitable for businesses with limited space.

Versatile Sheet Handling:

The system can handle different sheet sizes and weights, making it a versatile solution for digital printing lines.

Automated Stacking:

The system is fully automated, eliminating the need for manual labor and increasing efficiency.

Robotic Sheet Handling:

The system's robotic sheet handling capabilities help to reduce errors and improve the quality of the final product.

Final Bundle Squaring:

The system ensures final bundle squaring through the use of lateral and rear stoppers and the robot's clamp, ensuring high-quality bundles.

Simple and Maintenance-Friendly Design:

The system has a simple and compact design, making it easy to operate and maintain. It is also designed to be easy to clean, reducing downtime and maximizing uptime.

High-Quality Results:

The system helps to reduce waste, increasing efficiency and reducing costs.