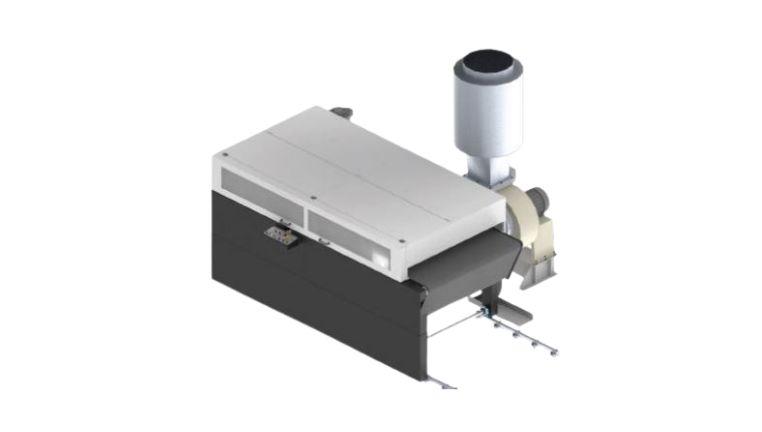

QUALITY CONTROL - PrintGuard

Quality control unit for digital printing lines

Overview

Quality control unit for digital printing lines

In the digital printing in the corrugated board industry, quality control is of utmost importance to ensure that products meet the desired standards. The Quality Control Unit for digital printing lines is an innovative solution that has been developed to streamline the quality control process, improve accuracy and automate reporting, and ultimately maximize productivity.

SERRA's Quality Control Unit for digital printing lines is an essential tool for any digital printing operation. The unit provides numerous benefits, including boosting productivity, improving availability, optimizing ergonomics, and being specifically designed for digital printing inline single pass lines With the unit's automated features and intuitive user interface, operators can improve accuracy and reduce the risk of human error, resulting in a higher quality end-product. Overall, the Quality Control Unit for digital printing lines is an excellent investment for any digital printing operation looking to improve its quality control process.

Boosting Productivity

- The unit enables faster job set-up times, it results in time and cost savings in the long run.

- Automatic detection of defective material reduces the likelihood of expensive production recalls.

- The easy-to-use interface and touchscreen controls enable operators to work more efficiently and effectively.

Improving Availability

- The Quality Control Unit for digital printing lines provides a simple, consistent quality control process.

- The unit projects digital proofs directly onto boards, providing operators with a faster and more reliable way of working.

- The digital reporting and monitoring features of the unit provide improved insights into the quality control process.

Optimize Ergonomics

- The unit projects digital proofs directly onto boards, providing operators with a faster and more reliable way of working.

- These features empower operators with enhanced insights into the quality control process.

- Operators can make better-informed decisions based on these insights.

Suitable for Digital Printing Inline Single Pass

- The unit is specifically designed for use in digital printing inline single pass lines.

- The unit's automatic detection of defective material using mechanical sensors provides an extra layer of quality control.

- The automatic detection ensures that only the highest quality products are produced.

Features

Automated defect detection:

The unit features mechanical sensors that automatically detect defective material, reducing the likelihood of expensive production recalls.

Digital proof projection:

The unit projects digital proofs directly onto boards, providing operators with a faster and more reliable way of working.

Single pass inline design:

The unit is specifically designed for use in digital printing inline single pass lines.

High accuracy:

The automated features of the unit improve accuracy and reduce the risk of human error, resulting in a higher quality end-product.

Extra layer of quality control:

The unit's automatic detection of defective material using mechanical sensors provides an extra layer of quality control, ensuring that only the highest quality products are produce

Time and cost savings:

The unit enables faster job set-up times, resulting in time and cost savings in the long run.