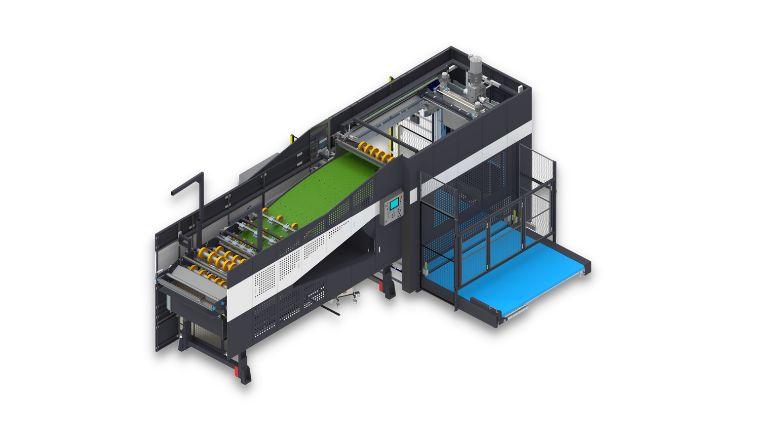

HIGH LINE STACKER

High line stacker for digital printing lines

Overview

Compact High line Stacker for Digital Printing Lines

The High Line Stacker from SERRA is a cutting-edge stacking solution specifically designed for digital printing lines in corrugated board production. Its unique features make it a valuable investment for manufacturers looking to optimize their production processes, improve their bottom line, and stay ahead of the competition.

SERRA is a valuable investment for manufacturers looking to optimize their production processes and improve their bottom line. Its compact size, continuous production capabilities, perfect stack formation, and low total cost of ownership make it an ideal solution for digital printing lines in corrugated board production. Choose SERRA's High Line Stacker to stay ahead of the competition and achieve success in your industry.

Space-saving design

- It takes up less space in the production facility and frees up valuable floor space.

- Manufacturers with limited space can maximize their production capacity with this feature.

- This is especially beneficial for those with limited space.

Continuous production

- The High Line Stacker has a shutter system.

- This system enables continuous production with no stops or pauses.

- The risk of production bottlenecks is reduced due to the shutter system.

Perfect stack formation & Printing Quality

- The High Line Stacker utilizes the double lateral squaring system and double belt transport system.

- These systems ensure perfect stack formation and the best register.

- The printed surface of the sheets is not touched, preserving the quality of the printed area.

Low total cost of ownership

- The High Line Stacker from SERRA requires minimal maintenance.

- It is a cost-efficient solution for manufacturers and can improve profitability

- The system's ability to improve efficiency and reduce waste helps lower operating costs.

Features

Space-saving design:

The compact size of the High Line Stacker takes up less space in the production facility, making it an ideal solution for manufacturers with limited space.

Continuous production:

The shutter system enables continuous production with no stops or pauses, reducing the risk of production bottlenecks.

Perfect stack formation & Printing Quality:

The double lateral squaring system and double belt transport system ensure perfect stack formation and the best register, preserving the quality of the printed area.

Versatile stacking capability:

The machine is capable of handling various sizes and thicknesses of corrugated board, providing flexibility in production lines.

High-speed stacking:

The High Line Stacker is designed to stack at high speeds, improving production efficiency and reducing downtime.

Rejection system:

The High Line Stacker comes equipped with a rejection system that automatically removes any defective or substandard sheets, ensuring consistent quality in production lines.

Automatic stack height adjustment:

The machine's automatic stack height adjustment feature allows for easy adjustment of stack height to accommodate different sheet sizes and thicknesses.

Easy-to-use control panel:

The machine's control panel is user-friendly, making it easy for operators to monitor and adjust production settings.

Sturdy construction:

The High Line Stacker is built to last, with high-quality materials used in its construction providing exceptional stability and durability.